Smart Canister

11.2023

Rethinking Food Storage

Food preservation is a daily concern that most kitchen products address passively. Containers provide barriers against air, moisture, and pests, but they don't actively manage freshness or inform users about contents. Coffee, in particular, degrades rapidly after roasting as oils oxidise and aromatics dissipate. Enthusiasts know that proper storage in vacuum-sealed, opaque containers significantly extends freshness, but maintaining vacuum seals requires separate equipment and conscious effort that most people don't sustain.

The Smart Canister project explored whether adding minimal intelligence to a storage container could meaningfully improve food preservation without adding complexity that discourages use. The core concept: a canister that automatically vacuum-seals when closed and displays remaining contents, eliminating the friction in maintaining optimal storage conditions.

Smart Canister features

Designing Automatic Preservation

I began by observing how people actually store coffee. Most use the original bag with a clip or transfer to basic containers, abandoning the vacuum-sealed protection coffee arrives in. External vacuum sealers exist but require retrieving separate equipment, running sealing cycles, and storing afterward. This multi-step friction means people simply don't do it consistently.

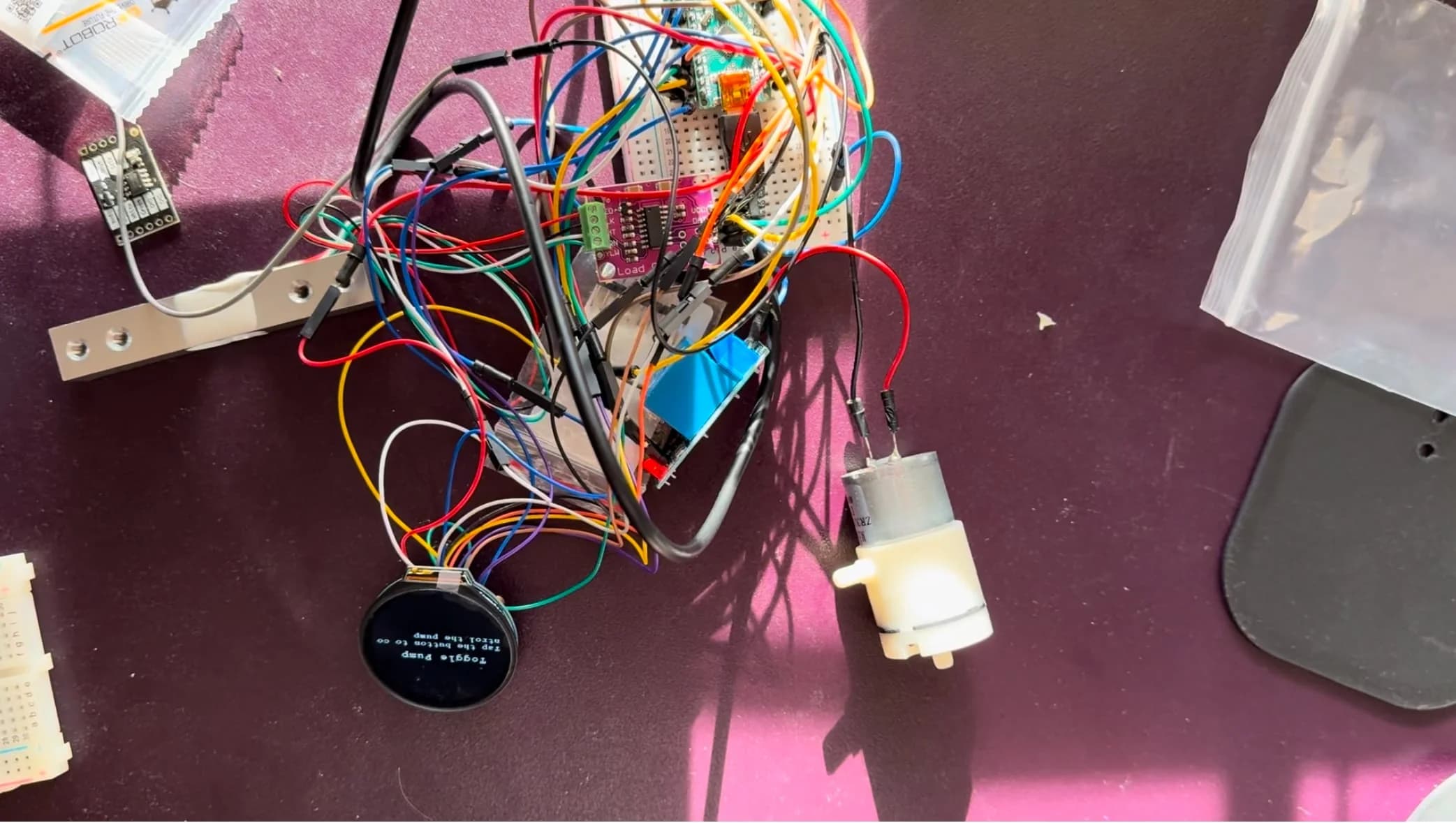

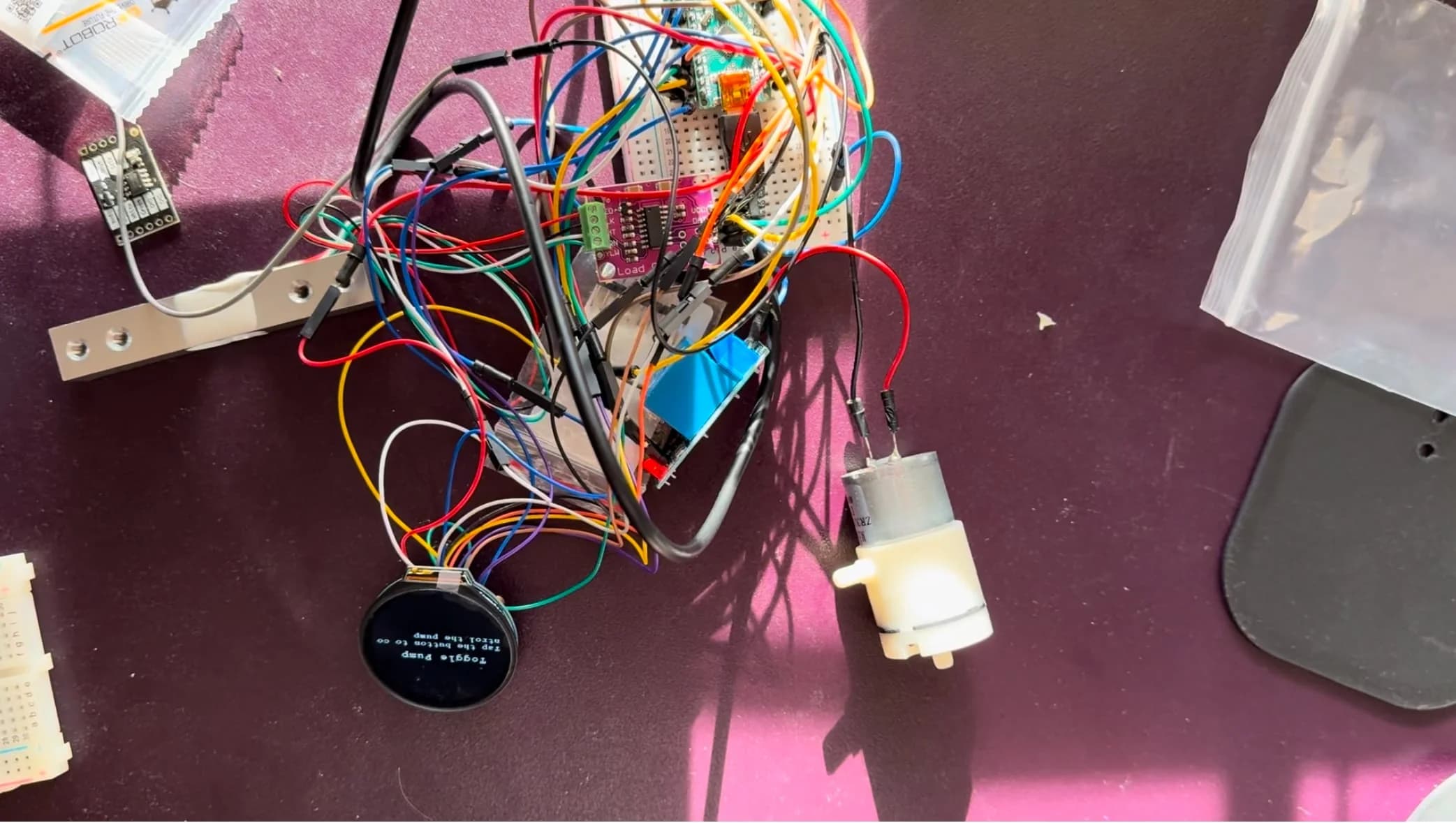

The technical solution integrates a vacuum pump, Arduino Nano, small display, and magnetic sensor into the lid. The user experience is intentionally simple: screw the lid on, and the pump automatically activates, extracting air until reaching the target vacuum pressure. A magnetic reed switch detects lid closure and triggers sealing without buttons or menus. This transforms a previously manual process into something that happens automatically.

The vacuum seal mechanism uses a double-seal system: a primary silicone gasket compressed by screw threads provides the main seal, while a secondary magnetic ring adds retention and triggers the electronics. I targeted moderate vacuum pressure (around 0.7 atmospheres), achievable with a compact, battery-powered pump that still meaningfully extends freshness by reducing oxygen exposure.

Electronics housing

Lid screws on and off - 3D printed in SLS

Content Sensing and Integration

Measuring remaining contents uses a load cell in the container base that tracks total weight. The system calculates the remaining quantity by subtracting the known tare weight. A small OLED display shows both numeric weight and a visual gauge indicating fullness, activating when the lid tilts or moves, then sleeping to conserve battery.

The lid's screw mechanism uses a coarser thread pitch that achieves full sealing in approximately one and a half rotations, fast enough for daily use while maintaining adequate clamping force. I fabricated the prototype using SLS 3D printing, which revealed integration challenges around wire routing, pump vibration, and display viewing angle that required iterative refinement.

Magnetic seal

Internal electronics incl. display, airpump, relay and Arduino Nano

Outcomes and Reflection

The Smart Canister project taught me that adding intelligence to everyday objects requires restraint. The temptation in IoT product design is to add features because technology enables them, not because users need them. Success came from doing two things well (vacuum sealing and content tracking) rather than attempting comprehensive smart kitchen capabilities.

I learned that the best smart products hide their intelligence. Users shouldn't think about the Smart Canister as a "smart" device; it's simply a canister that works better. The automatic sealing and passive content display integrate seamlessly into existing behaviour patterns rather than demanding new routines.