Modifi M1

07.2024

Challenging Disposable Consumer Electronics

The consumer electronics industry operates on a replacement model: products are designed for a lifespan of a few years before being discarded entirely when batteries degrade, connectors break, or newer models emerge. This approach generates enormous waste and forces consumers into cycles of repurchasing fundamentally similar products. High-end headphones exemplify this problem. Enthusiasts invest hundreds or thousands in premium audio equipment, only to face complete replacement when a single component fails or when they want to upgrade one aspect of performance.

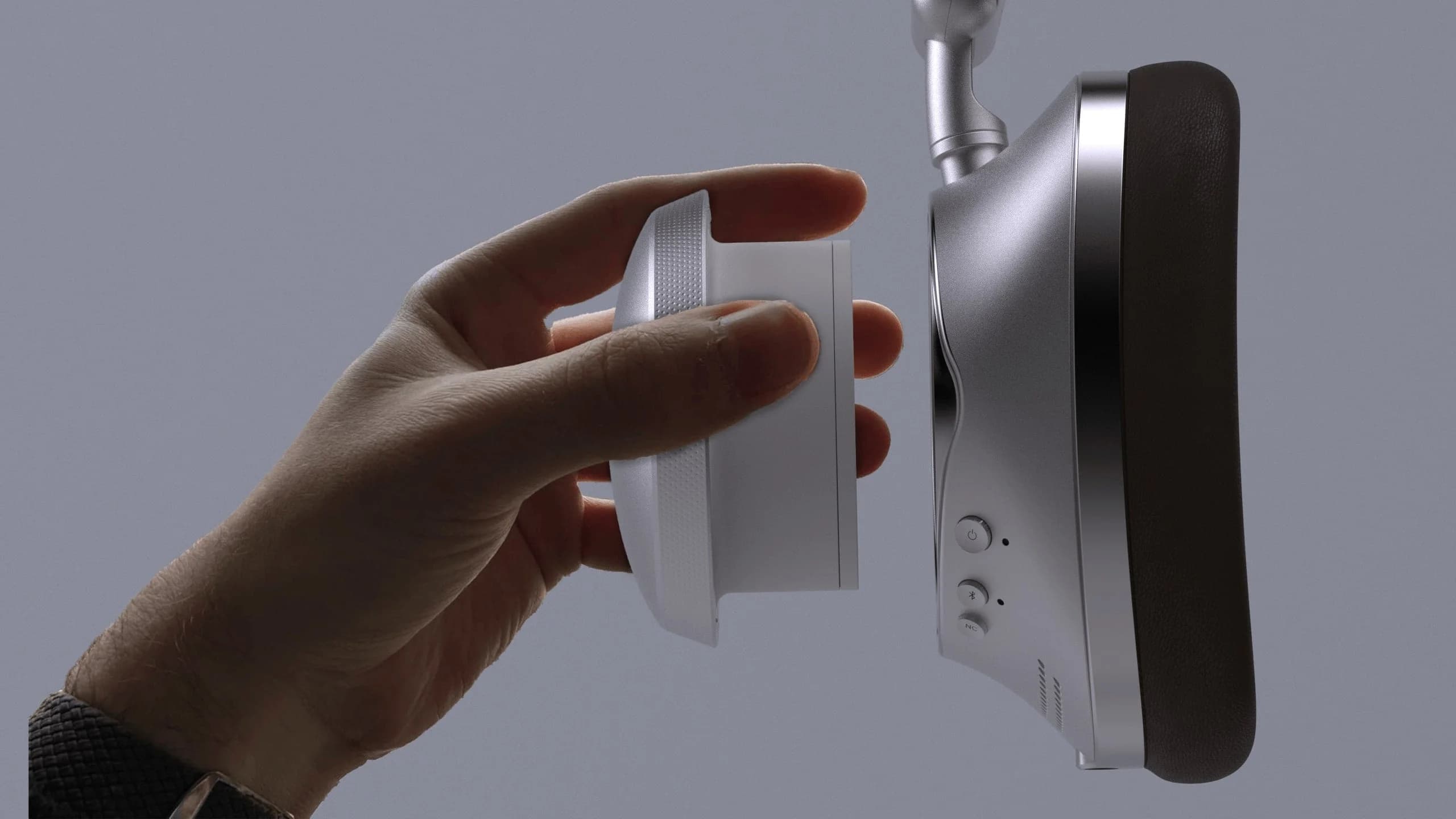

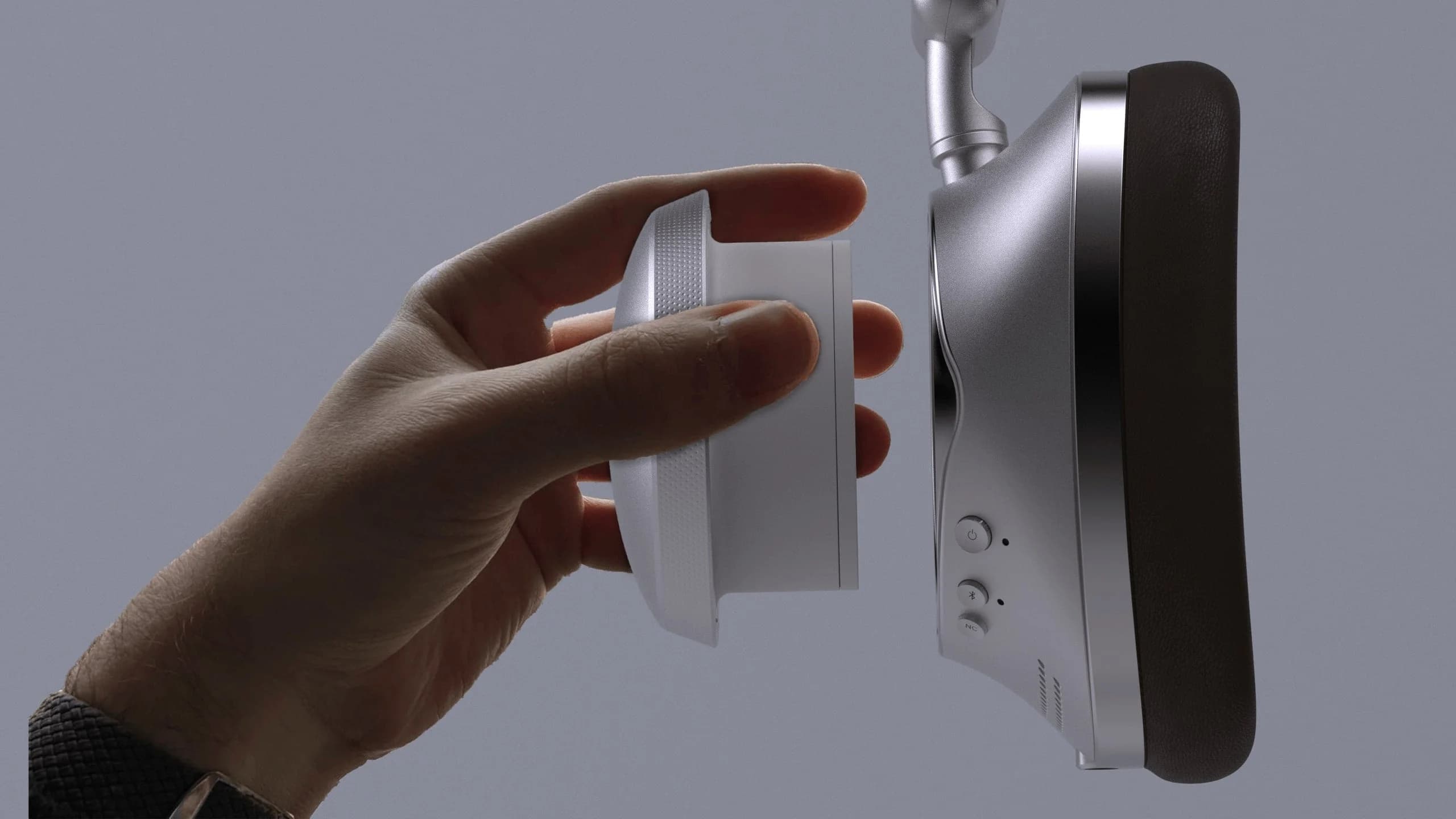

Modifi M1 challenges this model by designing modularity as a core principle rather than an afterthought. The concept: create headphones where every major component, drivers, cables, ear pads, headband, can be individually replaced, upgraded, or customized without compromising acoustic performance or structural integrity. This isn't just environmental responsibility; it's better economics for users and creates opportunities for ongoing product evolution rather than one-time sales.

You can view the full Modifi M1 Folio here.

Modifi M1 in black

Understanding the Audio Enthusiast

The project began with immersive research into audiophile culture and high-end headphone markets. I studied how enthusiasts discuss equipment, what attributes they value, and how they modify or customise existing products. Several patterns emerged that shaped Modifi M1's design direction.

First, audio enthusiasts care deeply about sound quality above all else. Any modular design would fail if acoustic performance suffered for the sake of replaceability. The mechanical connections between components needed to be absolutely rigid and repeatable; acoustic chambers couldn't have gaps or resonances introduced by modular interfaces. This established a core constraint: modularity must be mechanically excellent, not just functionally adequate.

Second, enthusiasts value material quality and build substance. High-end headphones use premium materials like aluminium, steel and leather because these materials both sound better (mass and damping characteristics) and feel more valuable. A modular system using lightweight plastics wouldn't meet market expectations regardless of functional benefits.

Third, the community embraces modification culture. Enthusiasts already replace cables, swap ear pads, and modify headphones to tune sound signatures. Modifi M1 channels this existing behaviour into intentional design rather than requiring aftermarket hacks. The modularity isn't inventing a new behaviour; it's formalising and elevating an existing one.

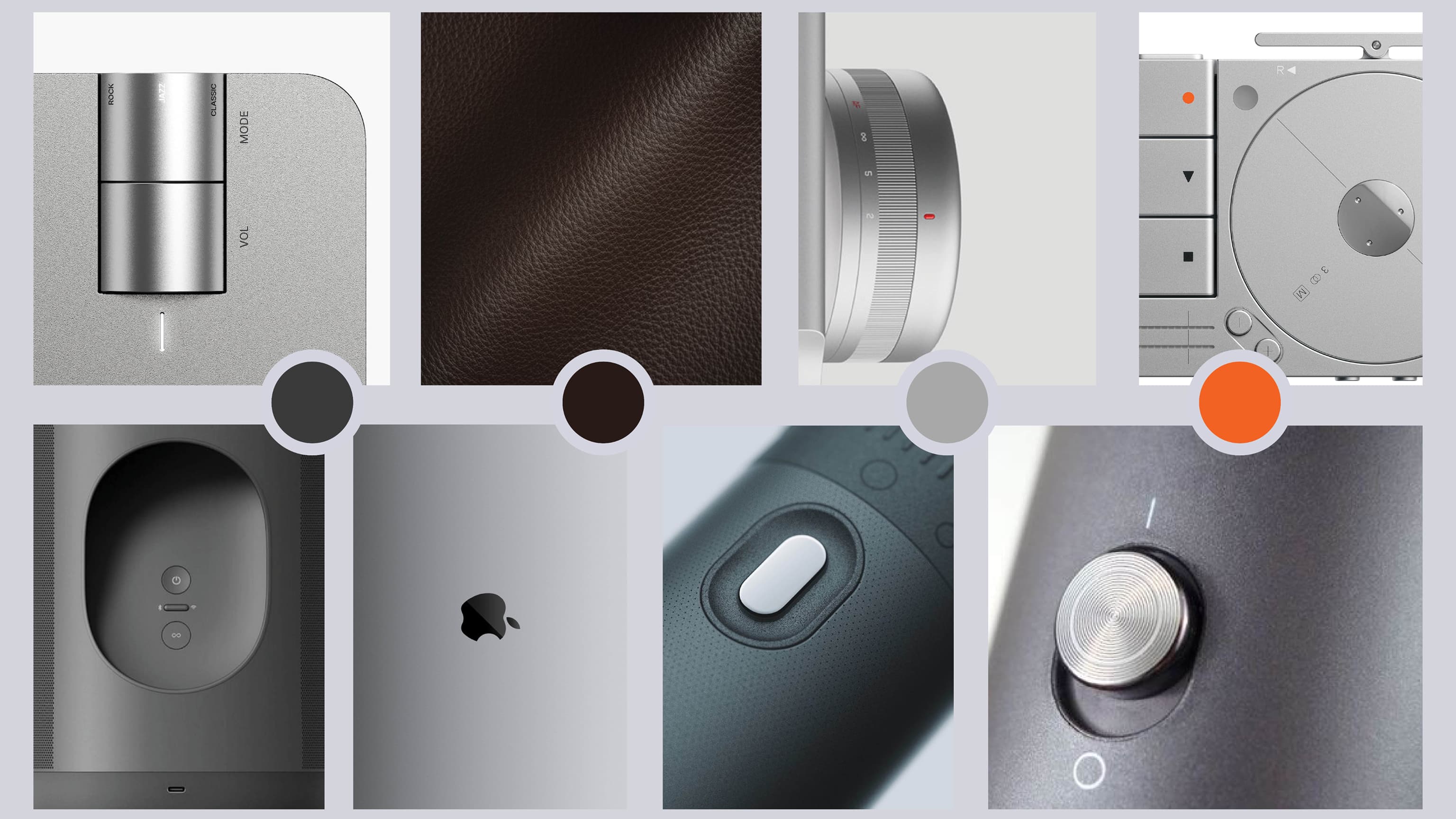

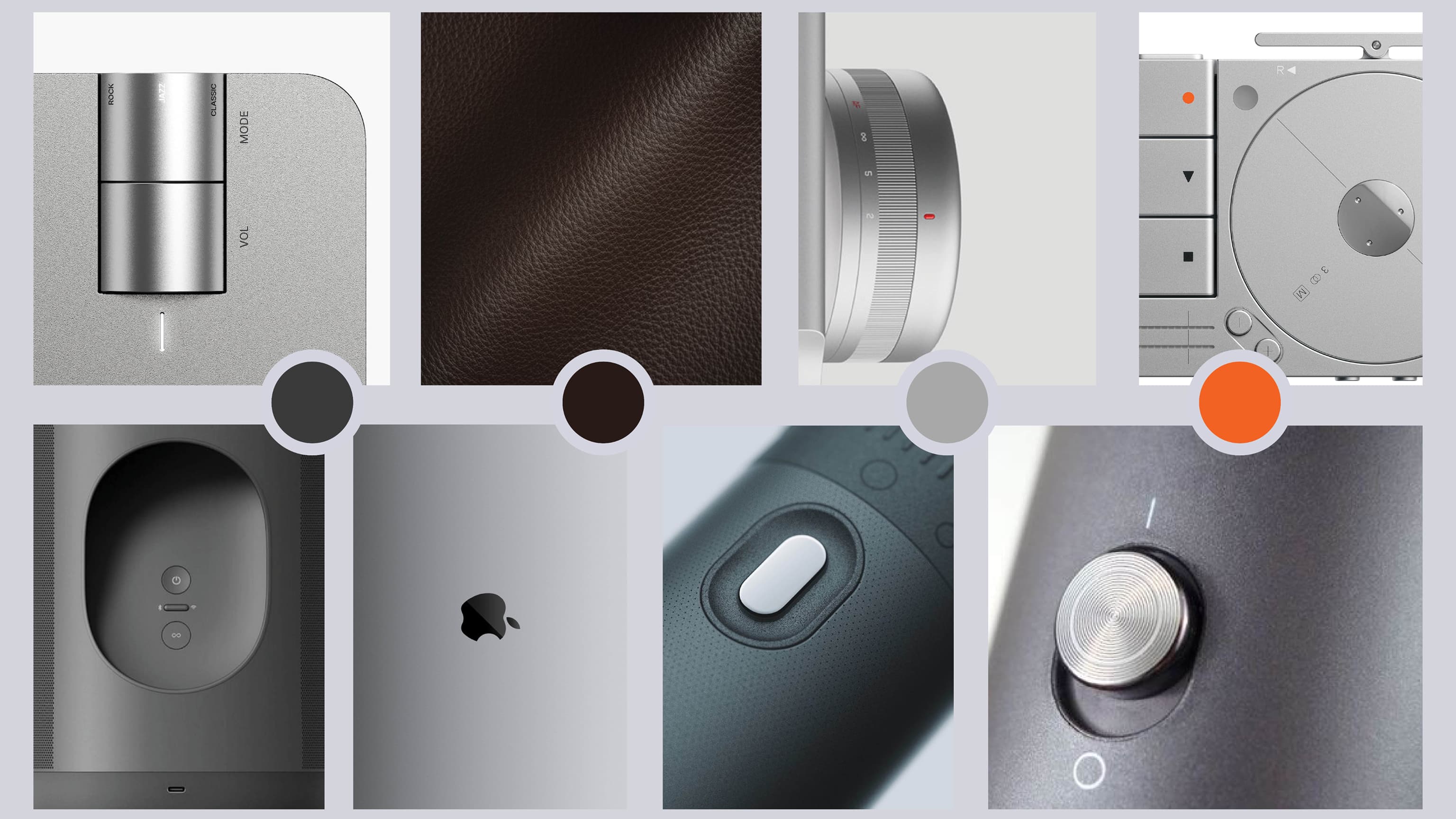

Moodboard

Designing Acoustic-First Modularity

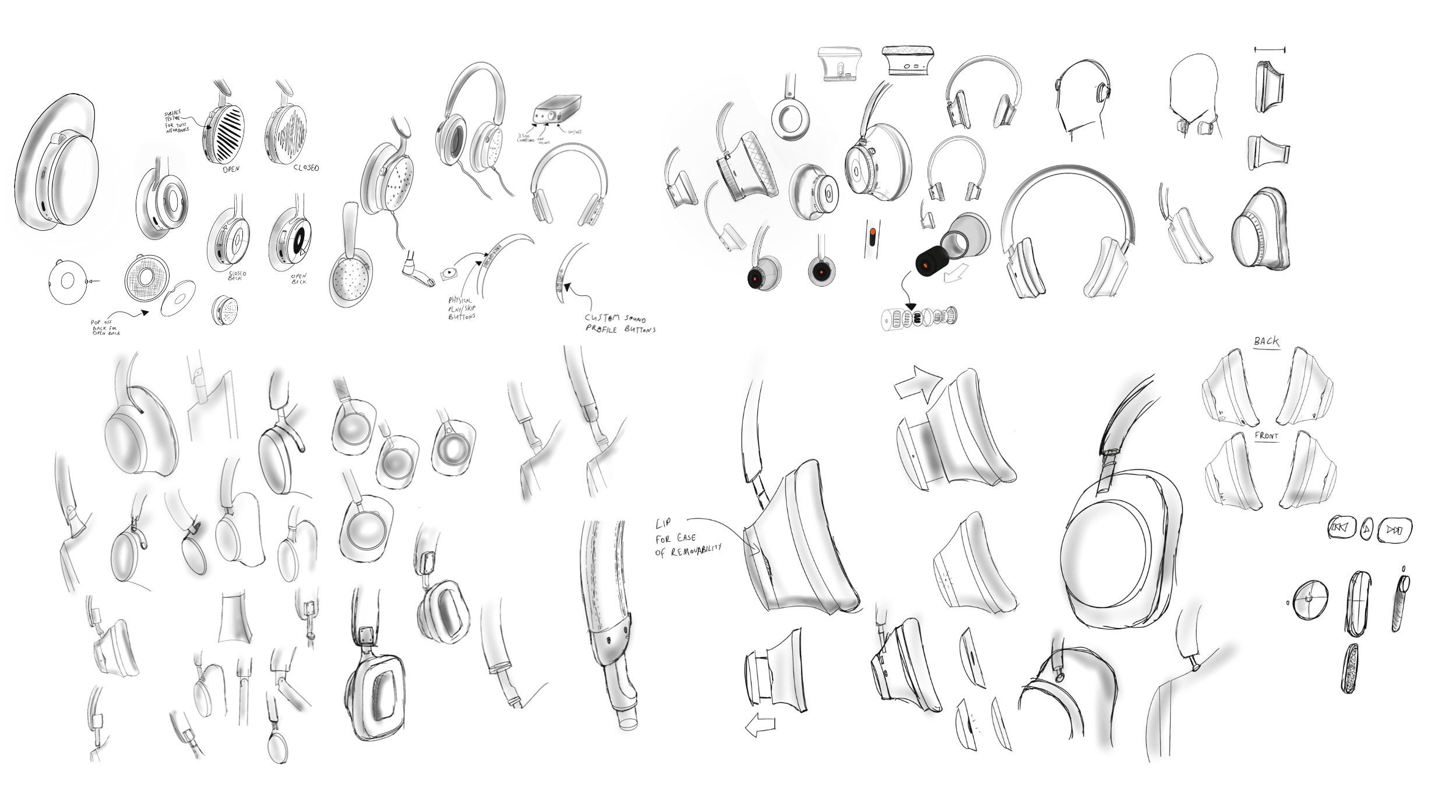

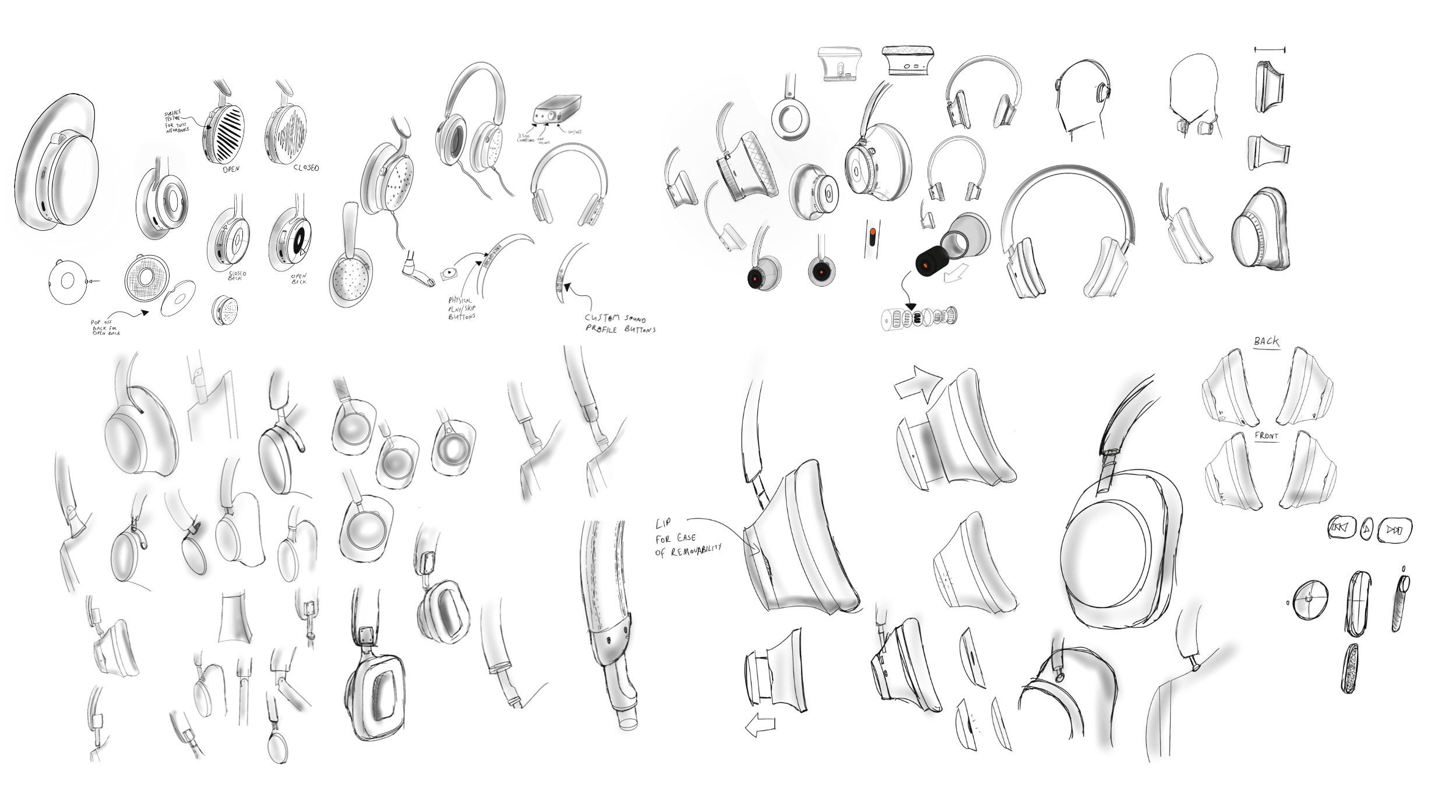

The fundamental design challenge was creating mechanical interfaces that allowed component swapping while maintaining acoustic precision. Headphone acoustics depend on precise volumes, sealed chambers, and predictable resonances. Traditional integrated construction achieves this through permanent bonds and carefully controlled tolerances. Modular construction risks introducing gaps, misalignments, and acoustic leaks that degrade performance.

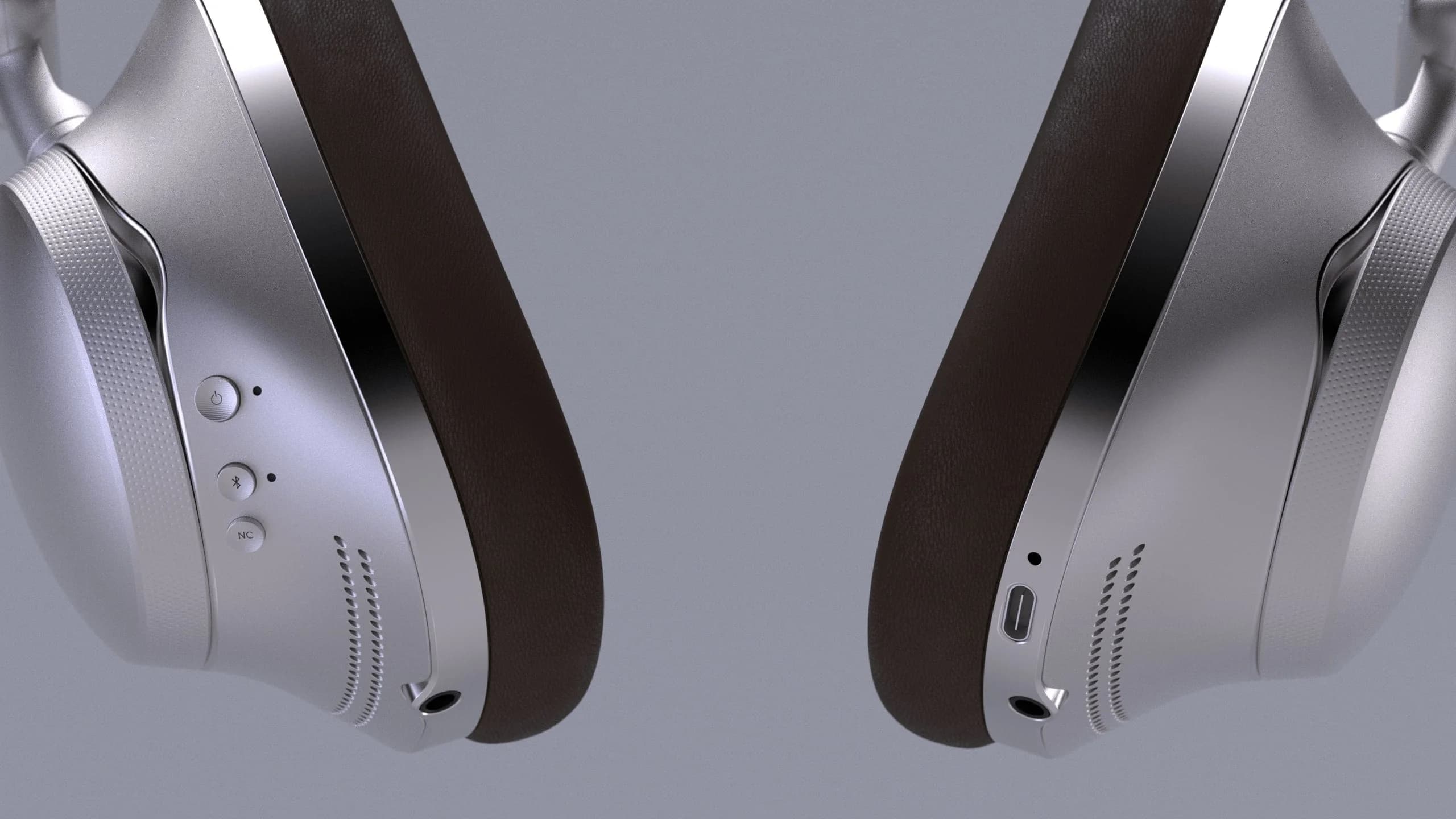

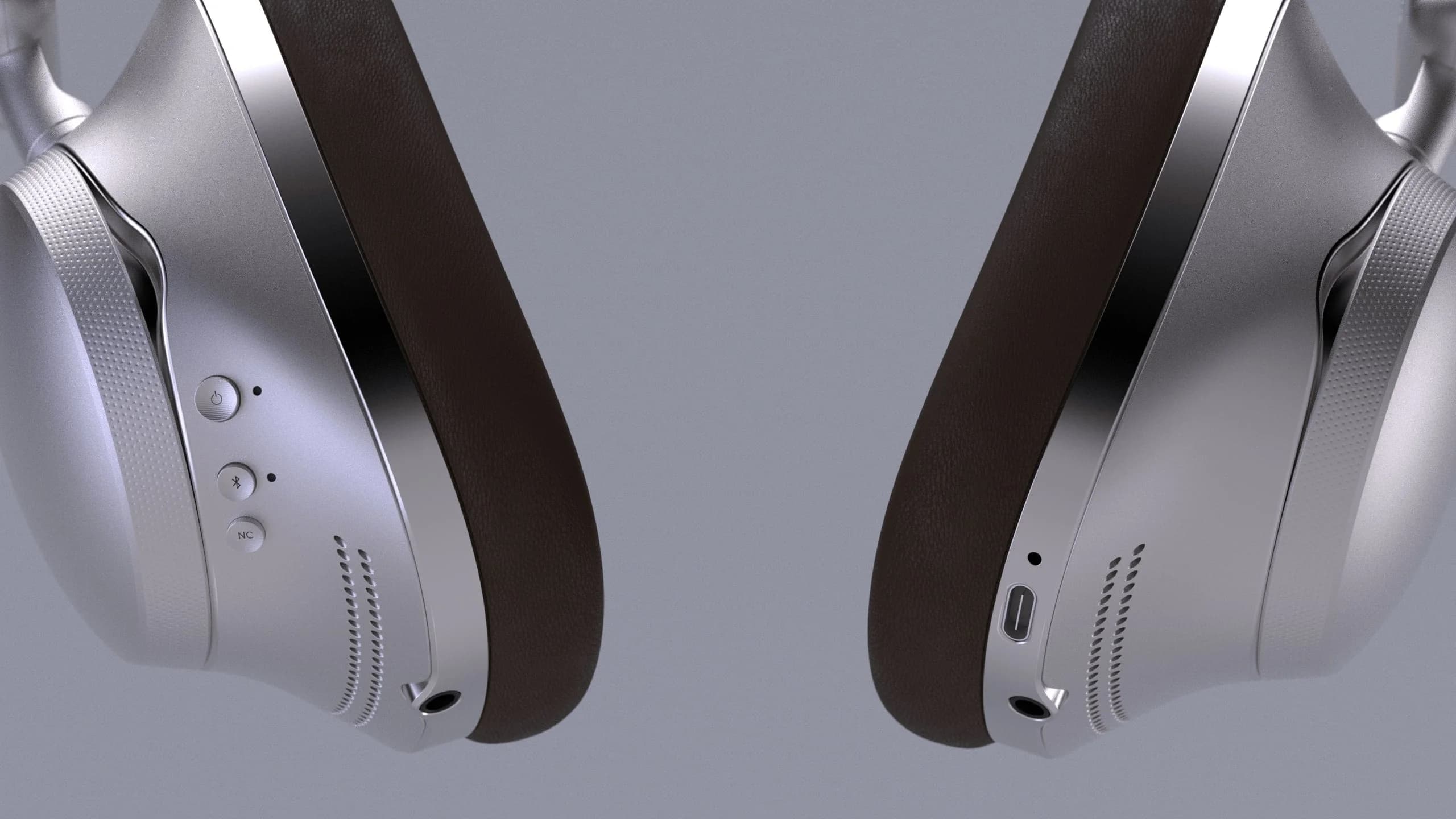

I approached this by designing the driver mounting system with extremely tight tolerances. The driver assembly mates with the ear cup housing through precision-ground surfaces that locate positionally and clip together magnetically. This ensures repeatable positioning every time a driver is installed.

The ear pad attachment presented different challenges. Pads need to seal against the ear cup consistently, isolate acoustically, and detach easily for cleaning or replacement. Most headphones use friction-fit systems that degrade over time or adhesives that make replacement difficult. I designed a magnetic retention system with locating pins. The magnets provide strong attachment while the pins ensure rotational alignment and prevent gaps in the seal. Users can remove pads instantly for cleaning and replacement without tools or complex procedures.

Sketches

Form Language and Material Expression

The visual design needed to communicate both premium quality and intelligent modularity. Too much emphasis on modularity risks looking over-engineered or utilitarian. Too little makes the modularity invisible, losing the key differentiator. I sought a balance where the modular nature feels intentional and sophisticated rather than compromised or overtly mechanical.

The ear cup geometry uses precision-machined aluminium with subtle faceting that catches light and suggests technical refinement. The facets aren't arbitrary styling; they correspond to internal acoustic chambers and structural ribs. This creates visual interest while expressing honest construction. The finish is anodised matte black with polished chamfers along edges, creating subtle highlights that emphasise form transitions.

The headband presented opportunities to express materiality and comfort. I designed a skeletal aluminium frame with leather-wrapped padding that adjusts via discrete clicks rather than continuous sliding. The click adjustment provides tactile confirmation and ensures left-right symmetry. The aluminium frame arcs gracefully, distributing clamping force evenly while minimising visual bulk. Leather wrapping adds warmth to the otherwise technical aesthetic and improves comfort during extended listening.

Modifi M1 exploded view

Dedicated Amplifier Integration

High-impedance headphones benefit from dedicated amplification, a fact well known to audio enthusiasts but creating friction in product adoption. Many potential users lack appropriate amplification, limiting their ability to experience full headphone performance. I designed a companion amplifier specifically optimised for Modifi M1, creating a complete system rather than headphones in isolation.

The amplifier design mirrors Modifi M1's aesthetic language: clean geometry, quality materials, subtle modularity. The device includes both balanced and single-ended outputs, allowing connection flexibility as users' systems evolve. Power comes from either AC mains or an internal battery, supporting both home and portable use cases. The industrial design prioritises passive cooling (no fans) for silent operation that doesn't compromise the listening experience.

Integrating amplifier design with headphone design allowed system-level optimisation. I could specify headphone impedance knowing exact amplifier capabilities, maximising dynamic range and minimising distortion. The amplifier's output stage uses circuitry tuned to Modifi M1's driver characteristics, achieving better performance than generic amplification would provide.

Dedicated amp for Modifi M1

Visual Communication and Rendering

KeyShot rendering allowed exploration of visual presentation without physical sample costs. I developed a library of camera angles, lighting setups, and staging contexts that communicated different aspects of Modifi M1. Hero shots emphasised form quality and material richness. Exploded views demonstrated modular construction. Detail shots highlighted precision in mechanical interfaces. Lifestyle renders placed headphones in aspirational contexts that resonated with target users.

Lighting design in renders proved critical for communicating material quality. Overly bright, even lighting flattens forms and makes materials look cheap, regardless of actual specification. I used dramatic, directional lighting with controlled reflections that emphasise the aluminium's machined quality, the leather's texture, and the cable's braided structure. This lighting approach created visual richness that better represented the actual product experience.

Background and staging choices communicated positioning and context. Early renders used pure white backgrounds that felt clinical and abstract. I shifted to warm, textured environments, leather goods, and quality audio equipment, which placed Modifi M1 in the aspirational world of premium audio. These contextual renders helped viewers understand not just what Modifi M1 is, but who it's for and how it fits into their lives.

Close up view

Swapping out modular driver

Reflections on Modular Product Design

Modifi M1 taught me that modularity isn't inherently good; it's valuable when it solves real problems without creating new ones. The challenge in modular design is maintaining the benefits of integrated construction (precision, quality, coherence) while adding flexibility. This requires designing modular interfaces as carefully as the components themselves.

The project reinforced that premium positioning requires excellence in every detail. Audiophiles notice and care about aspects invisible to casual users: the sound of adjustment clicks, the texture of material finishes, and the tactile quality of connections. Competing in premium markets means embracing a higher standard where no detail is too small to consider.

I learned to design for longevity differently from designing for immediate use. Products meant to last years need to age gracefully, accommodate future upgrades, and maintain relevance as technologies evolve. This long-term thinking shapes material choices, connection standards, and aesthetic approaches. Modifi M1 avoids trend-driven styling in favour of refined fundamentals that won't feel dated.

The ecosystem model revealed that product design increasingly extends beyond physical objects to service relationships and ongoing engagement. Modifi M1 isn't just headphones; it's a platform for audiophile exploration over time. This perspective transforms how I approach product concepting, encouraging thinking about product lifecycles and user relationships rather than singular purchase transactions.

Finally, working on Modifi M1 deepened my appreciation for the craft inherent in precision mechanical design. The difference between adequate and excellent often comes down to tolerances measured in hundredths of millimeters, surface finishes specified carefully, and assembly sequences thought through meticulously. This craft-level attention produces products that feel substantively better, creating emotional connections that transcend functional utility.

Wearing Modifi M1